Evertiq published an interview with Paweł Szumny, General Director and Vice-President of the Management Board of PB Technik, and Jakub Karpowicz, Key Account Manager and Leader of the Testing Systems Team at PB Technik, about the Polish giant’s entry into the Czech and Slovak markets and decided to ask Alessandro Beiletti, International Sales Specialist at Seica, how the Italian manufacturer views the strengthening of this cooperation and joint expansion.

Ewelina Bednarz, Evertiq: What can you tell us about Seica and in particular 2023 results?

Alessandro Beiletti, International Sales Specialist, Seica:Combining deep expertise in electronics technology as well as in industrial machines and processes has enabled Seica to become a global leader and supplier of test and manufacturing solutions, with an installed base of thousands of systems on 5 different continents. Today Seica is a Group with the headquarters located in Italy, a direct office in USA, Germany, China, Mexico, France, Israel and a vast sales distribution network covers the rest of the world.

The Group also includes Seica Automation, which designs and manufactures automation equipment for the electronics manufacturing industry and Canavisia, which promotes solutions with the goal of optimizing processes, maintenance and intelligent energy management factories, buildings and cities.

The 2023 was an extremely positive year, not only for the growth in turnover which reached 58 ME but also for the expansion of the company with 2 new buildings in Italy and for the number of employees which today stands at 300 employees worldwide.

EB: What is the main business of Seica?

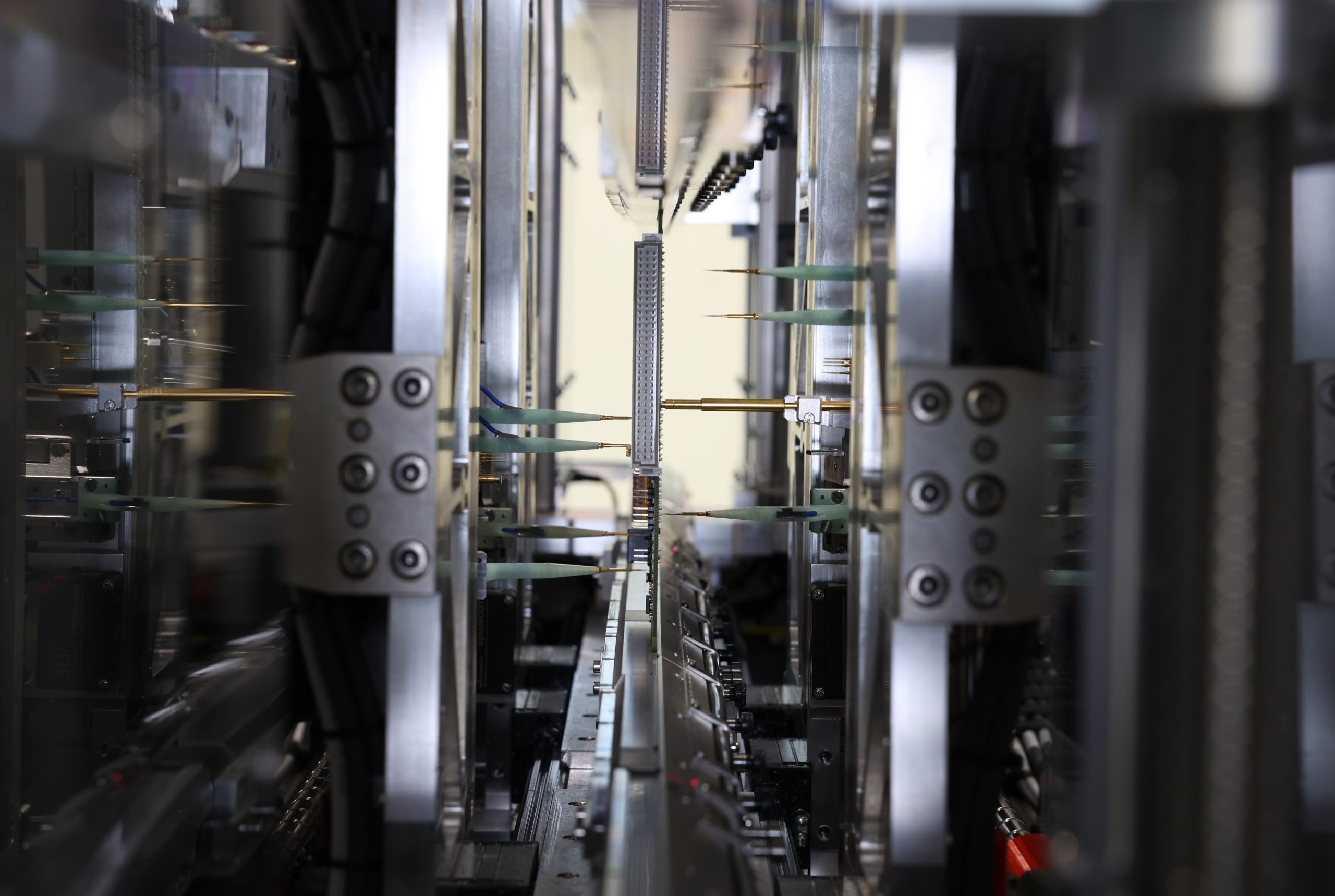

AB: Seica is an innovative, high technology company that develops and manufactures leading-edge solutions for the test and selective soldering of electronic boards and modules, including batteries for electric vehicles. With a significant and constant investment in Research and Development, Seica has become leader in flying probe technology and offers undoubtedly the most complete systems line available today on the market. Pilot is in fact the versatile flying probe line of automatic test systems with the widest range of test solutions and performances. Available in horizontal and vertical architectures with manual or automatic loading, the system configurations range from a minimum of 4 up to 17 mobile test resources, accessing simultaneously one or both sides of the board.

AB: What new machines Seica will show soon?

AB: All the systems we have realized in recent years are not standard systems, they are complex solutions and applications of multiple technologies to the same project.

Seica’s R&D is very focused on test solutions for every electric vehicles module, we have the Pilot BT line for battery bonding testing, as well Compact BMS for testing the battery management system and we have realized On-board Charger testing line for a multinational automotive company. Recently we created a line based on the specifications of a customer who is a world leader in the production of high-power batteries for the transport sector. It is one of the largest component suppliers in the global automotive industry and has factories around the world. The project involves the use of Seica test systems to perform functional tests on battery packs, integrated into a fully automated line, which moves the pieces between the various test stations. Other solution was applied the concept of distributed test to the flying probe test. This concept is based on the integration of multiple systems in a line, usually automated, each one dedicated to performing a part of the application required by the test specifications of the product under test. This approach simplifies specialization of each system based on the type of test to be performed for a specific product, and enables the optimization of test process times and the reduction of costs.

The evolution in the integration of active components, for example, has introduced new challenges for flying probers dedicated to testing flex-PCBs, Seica has tackled this challenge in the Roll-to-Roll manufacturing processes FLEX-PCBs with the Rapid H4 Flex, using previous experience in horizontal bare board systems.

EB: How long is cooperation with PB Technik? Is it a good partner?

AB: Seica has been collaborating with PB T for more than 15 years, the partnership has always grown, confirming an excellent commercial and technical synergy. PBT team has a high technical level and is also very active in promoting our solutions through events and exhibitions in Poland area.