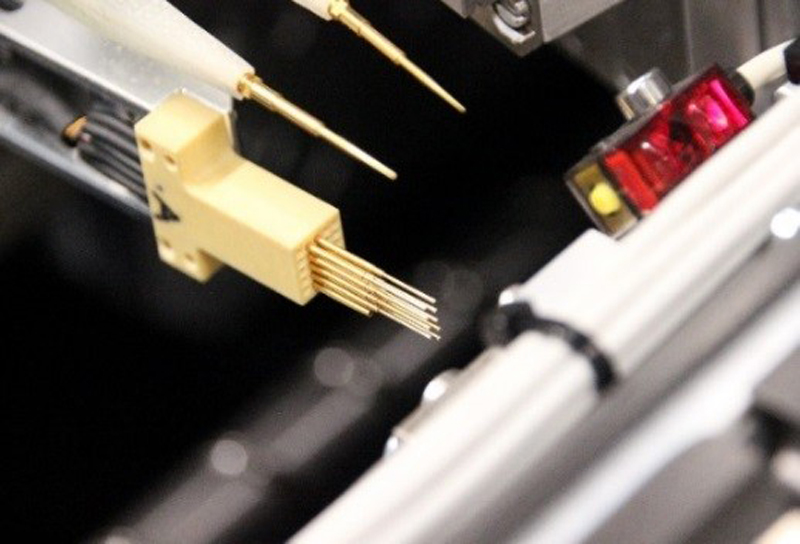

The new FlyPOD option by Seica allows to connect multiple hardware resources to a mini fixture which is installed directly on one of the flying probes.

The complexity and miniaturization of electronic boards leads the market to an increasingly widespread deployment of flying probe testers which are turning from parametric testers into powerful and flexible general purpose testing platforms, with unimaginable potentials even in a not too distant past. The heads of a modern flying probe system can be equipped with electrical flying probes but also with different types of tools, drastically increasing its potentials.

The On-board programming is a crucial step in the electronic board testing. Even for low-volume production, the following factors are involved which make essential the integration of the programming stage in the automatic test process:

- Management of data confidentiality

- Objective definition of the correct release to be installed

- Optimization of the programming times

- Need to reduce board handling

In this context it is worth mentioning the new FlyPOD option by Seica, which allows to connect multiple hardware resources to a mini fixture which is installed directly on one of the flying probes.

The FlyPOD module is mainly conceived and deployed for the On Board (OBP) programming, as a boundary scan test interface or as communication interface (e.g. CAN, I2C, …).

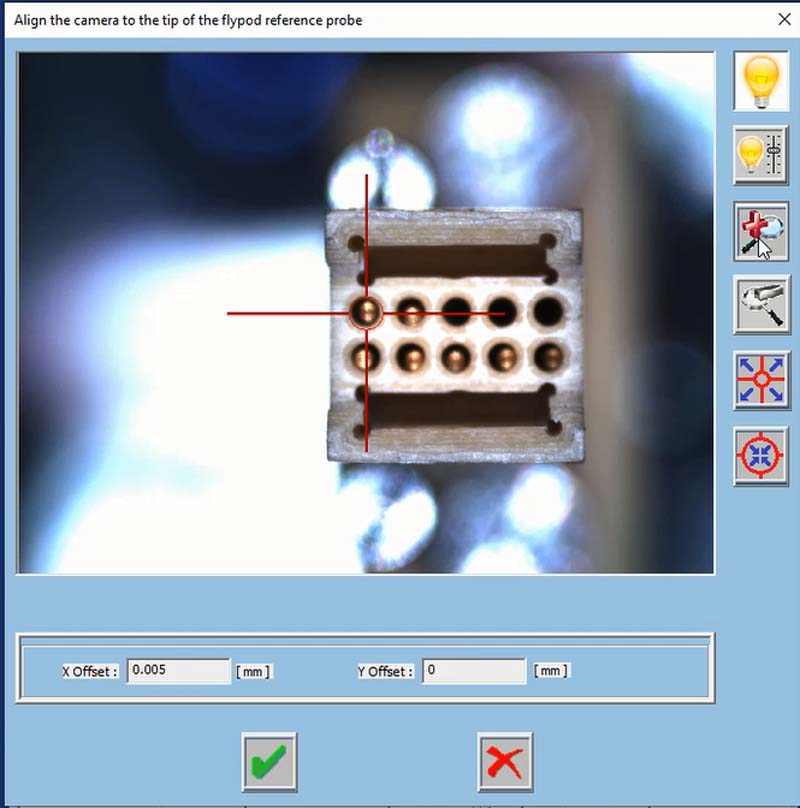

IMPLEMENTATION:

- Automatic flying prober with a 4 or 8 probes with FlyPOD option, can be perfectly integrated into a high-volume automatic production line.

- Integration of up to 2 FlyPOD on different heads for OBP programming, Boundary scan, CAN communication and other purposes.

- Fixture with minimum step of 1.27 mm (5×5 grid)

- Max. number of contacts: 14

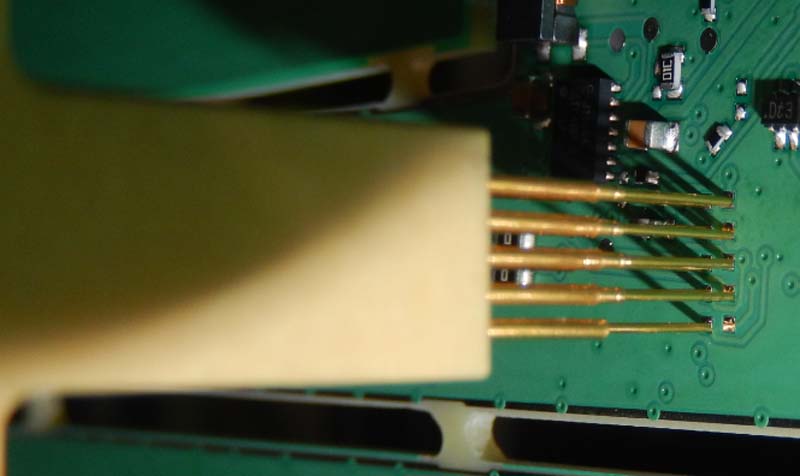

- The D.U.T. should provide a termination of test points connected to the device to be programmed

- The mini-fixture are plug&play type, and will be manufactured according to the configuration in use.

BENEFITS:

Fast and reliable programming: the solution ensures a minimum distance (~30 cm), between the target and the programmer; which is directly installed on an interface board attached onto the FlyPOD.

- Optimization of the programming speed with respect to a centralized programmer (inappropriate cable length)

- Possibility to double the FlyPOD heads and perform programming in parallel.

- Integrated software management, demanded to the Seica VIVA software.

- Dynamic script of the board serial available

- Automatic selection of the release to be installed.

- Verification of the correct programming and reporting.

- Possibility to add programming- related functional tests